ISO 6469 Electric Vehicle Special Potential Equalization Test

System

Complied Standards & Clauses

ISO 6469-1:2019 Electrically propelled road vehicles — Safety

specifications — Part 1: Rechargeable energy storage system (RESS)

IEC 62196:2020 Plugs, socket-outlets, vehicle connectors and

vehicle inlets-Conductive charging of electric vehicles

GB 7258-2017 Safety Technical Conditions for Motor Vehicle

Operation

...

Equipment Overview

This test system can perform potential equalization test for

electrical vehicles’ high-voltage components during the assembly

process of the entire vehicle. To ensure that the potential

difference between each high-voltage exposed conductive parts is

minimized, we need to make the potential equalization test by the

requirements of standards between each high-voltage parts shell and

electric platform, as well as any two exposed conductive parts that

can be touched by people at same time.

Principle

1. Take a specified current from a power source with no load not

exceeding 12KV, then apply it among the ground wire of the vehicle

charging port, the component exposed conductive shell and vehicle

frame, we calculate the ground resistance value by measured voltage

drop.

2. To test conduction resistance between the ground wire of each

vehicle charging interface, the exposed conductive shell of the

parts and the vehicle frame with a distance no more than 2.5m.

Judge Conditions

| No. | Name | Judge Conditions |

| 1 | Battery System + Electric Platform | R<40mΩ |

| 2 | Front Dive Motor Controller + Electric Platform | R<40mΩ |

| 3 | Rear Dive Motor Controller + Electric Platform | R<40mΩ |

| 4 | CDU + Electric Platform | R<40mΩ |

| 5 | HVPTC + Electric Platform | R<40mΩ |

| 6 | High-voltage Compressor + Electric Platform | R<40mΩ |

| 7 | AC Charging Socket PE Terminal + Electric Platform | R<40mΩ |

| 8 | Front Drive Motor + Electric Platform | R<40mΩ |

| 9 | Rear Drive Motor + Electric Platform | R<40mΩ |

Main Functions

1. Multi-channel: Integrated 10 channel potential equalization.

2. Screen display: 21.5-inch true color LCD screen is used, and the

interface of the test process is visible, which is convenient for

observation and judgment.

3. Open platform: It equipped with test program editing function,

test project editing function, test report editing and printing

function, user permission setting function etc.

4. Scan code function: It can record the vehicle VIN number, VSN

number and main accessories number, and automatically associate the

barcode to print the test report after test is completed.

5. Permission management: multi-level permission setting, which is

convenient for management.

6. Data management: Manage various data, protect the integrity and

security of the data, and have functions such as query and export

to meet the data management needs of the production line.

7. Safety protection: Over-current protection, over-voltage

protection, under-voltage protection, leakage current protection

and emergency protection, etc.

8. Massive data: Support massive data storage and analysis; MES

system docking, etc.

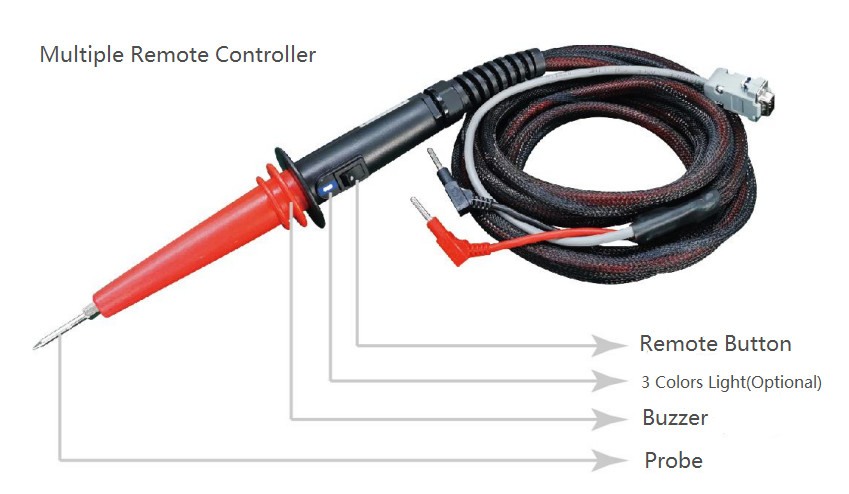

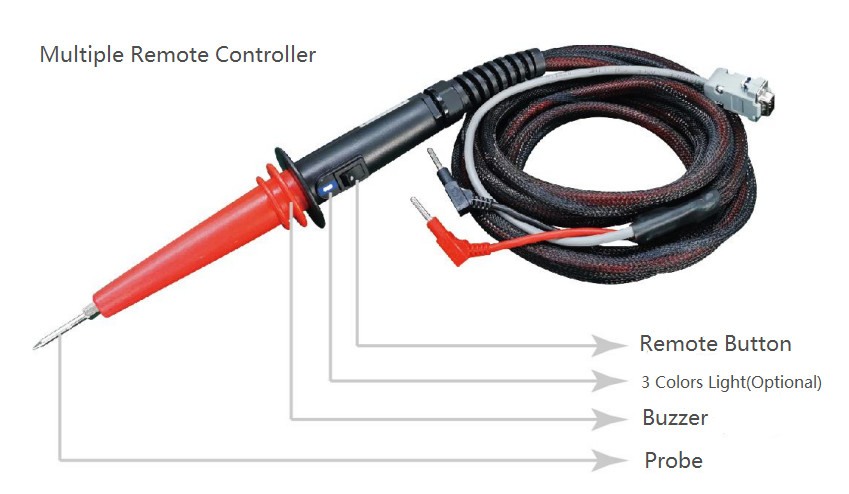

9. Flexible startup: Support multiple startup methods such as scan

code startup, button startup, remote startup, etc.

10. Intelligent judgment: The key indicators all have the function

of setting the upper and lower limits, automatically judge, and

effectively prevent the occurrence of missed inspections.

Equipment Main Features

| Standards applied: | ISO 6469, IEC 62196, etc |

| Test accuracy | Basic accuracy 1% |

| Special Clamp | High-end test clamps are adopted. |

| Structure optimization | Standardization and customization are combined, scalability and

security are simultaneously developed, the structure is simple, and

the logic is clear |

| Strong applicability | A variety of hanging methods are available-hanging trolley,

accompanying trolley, hanging rack, cantilever hanging, etc. |

| High intelligence | All items do not need to be connected to the measurement cable

repeatedly, and all the tests can be completed in one connection. |

| Modular | The system architecture design is modular and flexible, and the

system is easy to update and expand, and is easy to maintain and

upgrade |

| Flexible customization | According to the needs of customers, provide customized development

and design of industry platforms, such as automatic door opening

lighting, air conditioning heat dissipation |

| Site construction | Project construction management, installation knowing, equipment

debugging, etc. |

| Power Supply | 220V±10%, 50Hz±5% |

| Working Environment Requirements | 0-45℃, ≤85% |

| System Configuration | High-profile industrial computer + 21.5-inch true color LCD display |

| UPS uninterruptible power supply |

| Wireless one-dimensional two-dimensional scanning gun |

| Sticker and receipt printer |

| PLC interface, USB interface, network interface, alarm light

interface, foot switch interface, printer interface, barcode gun

interface |

| Safety Protection | The device does not start high-voltage detection if the charging

gun is not plugged in; Unplug the charging gun in the detection

state, the device should respond in time to cut off the power

supply to the socket |

Technical Parameters & Test Projects

| Test Channel | 1-10 channel, more channels can be customized. |

| Measuring Range | 0-600mΩ |

| Basic Accuracy | ±1% |

| Test Project | Potential Equalization Test |

| AC withstand voltage test | A | B | C | D | E | F |

| DC withstand voltage test | Vehicle charger | Rear TM motor controller | Front TM motor controller | High voltage distribution box | High voltage PTC plumbing heater | Air conditioning compressor |

| Insulation resistance test | <500mΩ |

| Test Project | Potential Equalization Test |

| AC withstand voltage test | G | H | I | K | N |

| DC withstand voltage test | Front TM motor | Power battery assembly | Rear TM motor | DC charging port grounding wire | AC charging port grounding wire |

| Insulation resistance test | <500mΩ |