UL 2580 Electric Vehicle Battery Pack External Fire Exposure

Testing Equipment

Complied Standards & Clauses

The Battery Pack External Fire Exposure Testing Equipment matches

the requirements of UL 2580 clause 42, ECE R100 Annex 8E, etc.

Technical Parameters

| Product number | SN5516-2500 | SN5516-3000 |

| Test space | W1500xD2500xH800 mm | W2000xD3000xH1000 mm |

| Host size | W7500xD3700xH960 mm | W8500xD4200xH960 mm |

| Mobile rack size | W1500xD3000 mm | W2200xD3200 mm |

| Load bearing | 1000KG, (2000KG, 3000KG customizable) |

| Mobile rack moving speed | 6000mm/min (speed adjustable) |

| Refractory baffle moving speed | 6000mm/min (speed adjustable) |

| Control system | PLC+touch screen close-range adjustment combined with computer

remote control |

| Ignition method | Automatic high pressure package ignition (remote control) |

| Combustion table to oil level distance | The distance between the gasoline liquid level and the test object

can be adjusted within the range of 450cm~550mm, and the default

value is 500mm; the bottom of the gasoline plate is filled with

water |

| Refractory brick size | Comply with standard ECER100, refractory brick size 240mm*120m*70mm |

| Gasoline plate size | There are 3 gasoline plates, and the gasoline plates of different

sizes can be replaced according to the size of the battery. The

operation is simple. The height of the gasoline plate is not higher

than 8cm above the gasoline surface. |

| Power supply | AC 380V, 7KW or match client’s site power supply requirements | AC 380V, 8KW or match client’s site power supply requirements |

| Equipment Weight | 3.5t | 4t |

| Other requirements | The ignition area of the gasoline plate can be adjusted according

to the requirements |

| Automatically add gasoline |

| Remote control, electric ignition according to test requirements |

| Video surveillance system, lighting system |

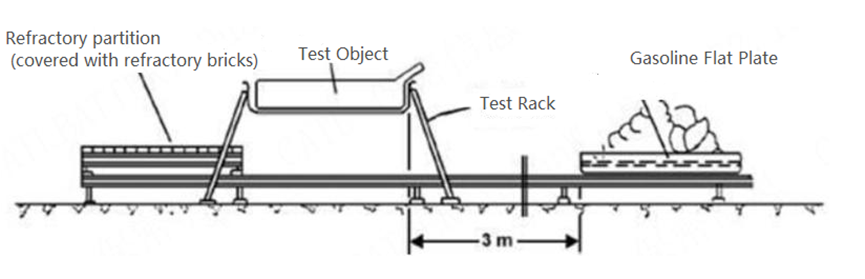

1. Relevant standard test requirements

1.1 The Battery Pack External Fire Exposure Testing Equipment

matches the requirements of UL 2580 clause 42, ECE R100 Annex 8E,

etc. The test object is the electrical road vehicle battery packs

or systems.

1.2 The test environment temperature is above 0℃, the wind speed is

not more than 2.5km/h, and the SOC requirement of the battery pack

is above 50%

1.3 In the test, the size of the flat plate containing gasoline

exceeds the horizontal size of the test object by 20cm, but not

more than 50cm. The height of the pan should not be higher than 8cm

above the gasoline surface. The test object should be centered. The

distance between the gasoline liquid level and the bottom of the

test object was set to 50 cm. Fill the bottom of the pan with

water. The schematic diagram of the external fire is shown in the

figure:

1.4 The first stage: preheating. Ignite gasoline at least 3m away

from the test object, and after 60 seconds of warm-up, place the

oil pan under the device under test. If the gasoline flat plate is

too large to move, move the test object and stand

1.5 The second stage: direct combustion. Test subjects are directly

exposed to flame for 70 seconds

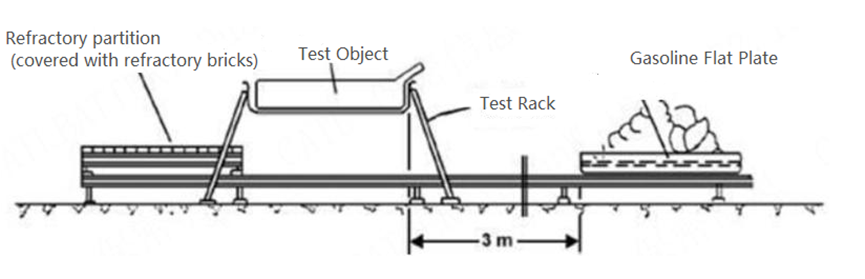

1.6 The third stage: indirect combustion. Put the refractory baffle

over the oil pan. Test subjects test in this state for 60 seconds.

Or by mutual agreement, continue to be directly exposed to the

flame for 60s. The refractory clapboard is made of standard

refractory bricks. The specific mesh size is shown in the figure

below. It can also be made of refractory materials with reference

to this size.

Fire resistance: (Seger-Kegel) SK 30

A12O3 composition: 30-33%

Porosity (Po): 20-22% volume

Density: 1900-2000kg/m3

Effective hole area: 44.18%

1.7 The fourth stage: Leave the fire source. Remove the gasoline

flat plate or the sample and observe for 2 hours or the surface

temperature of the sample drops below 45℃.